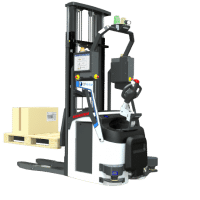

Our robotic stacker EffiBOT-P transports your pallets, on the ground or overhead, autonomously or in Follow-me mode.

EffiBOT-P is autonomous

The robotized stacker EffiBOT-P moves autonomously between your docks, your filming machines and your storage areas, while being connected to the conveyors and the various tangible and intangible infrastructures on your site: automatic doors, machinery, ERP, WMS, etc. Its multiple sensors enable it to operate safely in a mixed environment, alongside operators and other machines.

Its multiple sensors enable it to operate safely in a mixed environment, alongside operators and other machines.

Obstacle avoidance, emergency stops, priority management, compliance with the traffic and safety rules in force in your warehouse… Navigation is natural and totally reliable.

Its perception of its environment enables it to carry out precise operations such as counting pallets in order to pick the number indicated by the mission.

This autonomous mode is conditioned by the creation of a map using the MapEditor software and scenarios using our fleet manager (EffiFCS).

EffiBOT-P is collaborative

A follow-me mode is available, enabling EffiBOT-P to be used as an assistant in order picking, for example. Its touch screens and the ability to adjust the height of the picking support provide essential ergonomics and traceability in logistics.

The stacker can be operated manually at any time, simply by lowering the tiller.

EffiBOT-P is connected

EffiBOT-P can be connected to various software packages, such as WMS, MES and ERP, to automatically generate tasks to be carried out or to ensure the traceability of transported items, in particular by decoding barcodes, which it reads with its Smart Code Scanner.

Our stackers are equipped with:

- 2 LIDARs with a 270° detection angle for stacker navigation and obstacle avoidance

- 3D cameras to detect high or very low obstacles such as the forks of other vehicles

- Rangefinder sensors to secure the stacker laterally right up to the end of the forks

A front-mounted sensor for pallet handling. - One 3D LIDAR

We also have an EffiBOT-P80 stacker, narrower, and a cantilever stacker, EffiBOT-PF, for the transport of closed pallets.

For more information, please contact our sales team.

Useful dimensions and capabilities of the EffiBOT-P

- Load and lift capacity: 1.6 T

- Length: 2240 mm

- Width: 985 mm

- Height: 2125 mm

Useful dimensions and capabilities of the EffiBOT-P80

- Load and lift capacity: 1.6 T

- Length: 2277 mm

- Width: 800 mm

- Height: 2125 mm

Useful dimensions and capabilities of the EffiBOT-PF

- Load and lift capacity: 1.6 T

- Length: 2601 mm

- Width: 1076 mm

- Height: 2133 mm

Our robots are equipped with the most robust and efficient navigation system

A set of sensors analyzes the environment 270 degrees,

The location is based mainly on the natural environment and can also be artificially reinforced in open areas,

The navigation system allows a speed of up to 7 km/h (2 m/s).

Our EffiBOT-P complies with the Machine Directive 2006/42/EC.